|

|

|

Who is my sales rep?

North East and Midwest: Jay Havrilla, [email protected], cell: 407-413-1294 West US and West Canada: Matt Arriola, [email protected], cell 954-682-2508 Southeastern US and Texas: Gary Sander, [email protected], cell 678-314-2298

0 Comments

Dackor is able to coat papers for 5 piece doors, profile wrapped components and other applications. This post will explain the difference in papers.

Most of Dackor's customer use a 2 part PUD adhesive that they spray on MDF using a spray gun. We do have a few customers who use pre-applied adhesives and this article discusses that.

Product: Pre-applied glue on rigid vinyls Description: This thermoplastic adhesive film is a tough fully reacted elastomer, which is very flexible over a wide temperature range. It exhibits excellent adhesion to wood, MDF, and vinyl decorative foils. Its low activation temperature makes it an ideal adhesive for these heat sensitive materials. Product Benefits: Low activation temperature, excellent adhesion to vinyl and PU coated substrates Excellent adhesion to wood and MDF board Low gel content Good heat resistance Composition: Ester Polyurethane Color: Translucent Weight: 37.99 lbs ( 62 gm/m2) Substrate: Unsupported Nominal thickness: .002” (50 Micron) Hardness: 97 A Softening Point: (65oC) 150oF TMA onset Temperature Melt Flow Index: 5.0 dg/minute Condition: 347 F /4.76 lbs (175oC / 2.16 Kg )Load Recommended Application Conditions: Bonding =158 F to 176 F (70oC to 80oC) Glue line temperature on a membrane press, as recorded by thermal measurement tags. Preheat temperature, membrane temperature, and cycle times vary from press to press. Change is rarely met with enthusiasm. Usually, the first response is lackluster; it takes effort to unlearn what is comfortable. However, using a change management framework encourages the people impacted to adapt to a new process and increases the success of implementation.

For example, switching expense reporting platforms may seem like a simple change. But think back to the last time you traded in one process for another. There are likely to be a few frustrating moments while learning where functions exist in a new dashboard. It takes time to rewire the brain. And if the new process is not intuitive, there is a greater chance that employees may not like the change. When you use a change management model, it helps you anticipate resistance and establish a plan for guiding your organization to successful implementation. Action strategies to overcome the 7 biggest mistakes a CEO can make. What is Change Management? Change management is a framework to execute a significant internal or external shift in its processes, culture, technologies or other critical operational aspects. “It is staying ahead of change so that your entire team can deal with change effectively rather than just leading from the top,” says André van Hall, speaker and author of “The Curiosity of Change.” “It takes initiative and challenges the status quo before you are the victim of it.” More specifically, change management focuses on the people side of change, says Dave Collins, founder and CEO of Oak and Reeds. He divides change management into two categories:

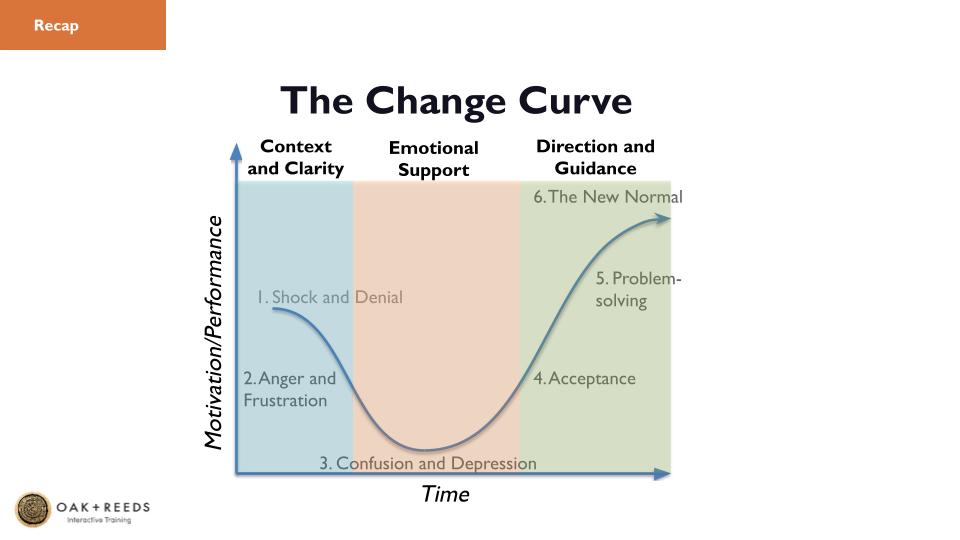

Types of Change ManagementMany theories and methodologies exist for approaching organizational change. Collins relies on two to help leaders with change management — The Kübler-Ross Change Curve and the Beckhard-Harris Change Equation. he Kübler-Ross Change Curve is based on the six stages of grief and acknowledges that change can trigger emotional reactions.

Leaders can get frustrated because they are usually further along the curve than the rest of the team. So, while leaders may already be at stages 4-6, their teams may only be in stages 1-3. “That disconnect can cause a lot of anxiety and hurt feelings. Be patient and allow people the processing time and trust that they’ll get through it,” Collins says. “Most people will, but some folks never get through it.” Then you need to have hard conversations about individuals who are unable to change and operate in the new environment. It’s important to ask, “Are we okay with a lower level of performance or that they never really got excited about it?” Why is Change Management Important? Change is unavoidable. The world is continually changing, and businesses must evolve for sustainability and growth. By managing change, you can stay on top of internal or external shifts rather than being surprised by them. While change can be painful, the results can improve workflows to enhance employee experiences, lower project expenses, improve company culture, mitigate risk and increase the organization’s ability to overcome obstacles. How to Deal with Resistance to Change in an OrganizationCollins uses the Beckhard-Harris Change Equation to help leaders overcome resistance to change. In the 1970s, researchers Richard Beckhard and Reuben T. Harris found that large, complex organizations aren’t good at changing, and perhaps more importantly, they are not good at predicting the likelihood that a change will be successful. “Very often, leaders think, ‘Oh, this is going to be easy. We’ll get through this in three months,’” Collins says. “Their predictive power was almost worse than their ability to change.” The Beckhard-Harris Change equation emerged from the researchers and Collins encourages leaders to use this to overcome resistance to change. Dissatisfaction x Vision x First Steps > Resistance. Dissatisfaction starts by pointing out the things that are broken, annoying or not operating well. This boils down to clearly identifying the why behind a change. When this goes unsaid, people can get frustrated that it is simply changing for the sake of change. Vision highlights how things will be better or more efficient if the change is implemented correctly. Explain what is getting better and how the company is going to be more profitable. “It’s not just talking about the bottom line, like how will this affect our numbers, but how will people feel better,” Collins says. “How will they be less stressed? How will they be more engaged? I teach the Change Curve first, so people understand much of change is emotional processing. If you can speak in that language well, you’re going to help people through those emotions and get to acceptance.” The last variable is First Steps. The more difficult you make the first thing people have to do, the harder it is for them to execute. “Change is not a ‘rip the band-aid off.’ You need to get people going little by little,” Collins says. For example, if you’re implanting a significant IT change, the first step should be to log in and upload a profile picture rather than re-uploading all the data into a new platform. “When the variables on the left (dissatisfaction, vision and first steps) are greater than the power of your resistance, your change will probably work,” Collins says. “The idea is to increase the power of these three variables working in your favor.” Communication plays a critical role when executing any type of change management, especially when facing resistance. “Share information and expect your team (everybody) to take initiative so you can push decision-making as far down the organization chart as possible,” van Hall says. “The benefit is that when ten members accept the responsibility of ensuring their area is not only operating at peak efficiency, but also staying ahead of changes.” 3 Steps in the Change Management Process. A robust communication plan is central to implementing change. Three steps guide the details contained within that plan. 1. Make a list of all stakeholders. “Very often leaders leave out a good chunk of stakeholders that aren’t immediately obvious,” Collins says. “Remote work, hybrid work, bringing people back into the office, or not, is an example that has come up a lot. There are a lot of stakeholder audiences that need to be involved.” Using the example of a mid-level manager returning to the office, those stakeholders include direct reports, IT staff, clients, cross-functional partners, vendors, the individual’s family, kids, and friends. “You don’t have to spend all day thinking about people’s family, but for some of these changes, it’s a huge effect and may be harder to manage that side of things than necessarily your teammates, who you’ll just be talking to slightly differently,” he added. 2. Answer two key stakeholder questions.

3. Acknowledge change is occurring rather than pretending its business as usual. “Don’t put your head in the sand and pretend nothing is changing; recognize that these changes are happening,” Collins says. Change Management Best PracticesChange, even with good management, is hard. But when you use these best practices you can help limit resistance and build momentum to increase the chances of a successful implementation. 1. Create a culture of safe collaboration and free thinking. “Realize that in most industries, it is our least paid employee, so that is delivering the product or service,” van Hall says. “Train them, coddle them, develop them, and have high expectations in return.” 2. Share information early and often, don’t hoard information as a leader.“You’re better off treating people like adults, telling them hard news early to give them more time to process,” Collins says. “Share news, share clear information early and often. Be patient with yourself and with your people. 3. Stop taking yourself so seriously!van Hall encourages leaders to accept failure as teachable, rather than punishable moments. 4. Step back and let creativity kick in.“Once people accept the change, step back and let their creative brains run. Allowing people to implement and personalize the change can happen in ways you didn’t expect,” Collins says. “That’s people taking ownership and that is what those emotions look like when people are engaged and feel bought in.” * from Vistage  There is a Chinese Proverb that goes something like this… A farmer and his son had a beloved stallion who helped the family earn a living. One day, the horse ran away and their neighbors exclaimed, “Your horse ran away, what terrible luck!” The farmer replied, “Maybe so, maybe not. We’ll see.” A few days later, the horse returned home, leading a few wild mares back to the farm as well. The neighbors shouted out, “Your horse has returned, and brought several horses home with him. What great luck!” The farmer replied, “Maybe so, maybe not. We’ll see.” Later that week, the farmer’s son was trying to break one of the mares and she threw him to the ground, breaking his leg. The villagers cried, “Your son broke his leg, what terrible luck!” The farmer replied, “Maybe so, maybe not. We’ll see.” A few weeks later, soldiers from the national army marched through town, recruiting all the able-bodied boys for the army. They did not take the farmer’s son, still recovering from his injury. Friends shouted, “Your boy is spared, what tremendous luck!” To which the farmer replied, “Maybe so, maybe not. We’ll see.” The moral of this story, is, of course, that no event, in and of itself, can truly be judged as good or bad, lucky or unlucky, fortunate or unfortunate, but that only time will tell the whole story. Additionally, no one really lives long enough to find out the ‘whole story,’ so it could be considered a great waste of time to judge minor inconveniences as misfortunes or to invest tons of energy into things that look outstanding on the surface, but may not pay off in the end. The wiser thing, then, is to live life in moderation, keeping as even a temperament as possible, taking all things in stride, whether they originally appear to be ‘good’ or ‘bad.’ Life is much more comfortable and comforting if we merely accept what we’re given and make the best of our life circumstances. Rather than always having to pass judgement on things and declare them as good or bad, it would be better to just sit back and say, “It will be interesting to see what happens.” APPLYING TO BUSINESS: The above story is about how perspective and how we perceive things is just as important as the actual events themselves. As manufacturers, we often view waste, loosing a big order or other set backs a major events that should be kept from happening. If, however, we look at an event as an opportunity to improve then in reality, that is a great time to make improvements to increase efficiencies or services to clients. CUSTOMER: "How much will it cost to do this job?"

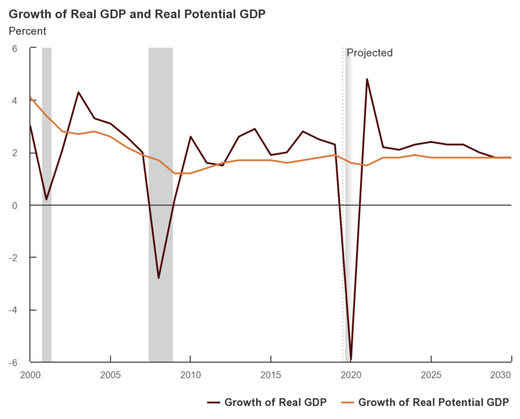

CONTRACTOR: "$2,800 Dollars." CUSTOMER: "That's WAY too expensive for this job!!" CONTRACTOR: "How much do YOU think it would cost?" CUSTOMER: "No more than $800 Dollars - MAX!! It's a simple job!" CONTRACTOR: "I can't prioritize my time for so little." CUSTOMER: "People in your line of work are so greedy." CONTRACTOR: "Sorry you feel that way. Why not do it yourself?" CUSTOMER: "But... but... I don't know how to do any of this." CONTRACTOR: "For $900 Dollars, I'll teach you EXACTLY how to get this job done. Then you can spend $800 to do the job and you'll still be saving $1,100 Dollars - PLUS... you'll get the knowledge and experience for the next time you want to do a job yourself." CUSTOMER: "Deal!! Let's do it." CONTRACTOR: To get started you'll need tools. So you'll have to buy a welder, a grinder, a chop saw, a drill press, a welding hood, gloves and a few other things." CUSTOMER: "But I don't have all this equipment and I can't buy all of these for one job." CONTRACTOR: "Well then for another $300 more I'll let you rent my tools... and you'll still be saving $800 Dollars." CUSTOMER: "That's cutting into my savings. But I'll rent your tools." CONTRACTOR: "Okay! I'll be back on Saturday and we can start." CUSTOMER: "Wait. I can't on Saturday. I only have time today." CONTRACTOR: "Sorry, I only give lessons on Saturday, because I have to prioritize my time and my tools have to be at other jobs with other customers all week long. CUSTOMER: "Okay!! I'll sacrifice my family plans on Saturday." CONTRACTOR: "Yeah... me too. Oh... and I forgot... to do your job yourself, you also have to pay for the materials. Everything is in high demand right now, so your best bet is to get your truck and load up at 6AM before everyone else gets there." CUSTOMER: "SIX AM??? On a Saturday??? That's way to early for me. And also... I don't have a truck." "CONTRACTOR: "I guess you'll have to rent one. Do you have a couple of strong men to help you load and unload everything?" CUSTOMER: "Ummm... ya know... I've been thinking. It's probably best if YOU get this job done. I'd rather pay someone to get it done correctly than go through all the hassle. CONTRACTOR: "Smart move, sign this and please get out of the way so I can work." THE REALITY IS THIS... When you pay for a job, especially handcrafted, you pay not only for the material used, but you are also paying for: - Knowledge - Experience - Tools - Services - Time - Punctuality - Accountability - Professionalism - Accuracy - Labor - Sacrifices - Safety and Security - Payment of tax obligations No one should denigrate a professional's work by judging prices - ESPECIALLY when they don't know all the elements or costs necessary for the production of such work. This is a repost, hope you enjoyed it ! Are you an executive in the Interior Design, Manufacturing or Building market? Are you interested in hearing market forecasts as it pertains to our industry? In this Quarterly article, I will compile financial docs that may pertain to our industry. You may unsubscribe at any time however as fellow executives in the Design/Build space I hope you stay connected. As a member of Vistage, the nation's largest CEO group for small business's I was pleased to have a guest speaker from a financial modeling and economic forecasting company. Due to the confidentiality of their report, I will instead refer to the Congressional Budget Office. This report presents the baseline economic forecast that the Congressional Budget Office is using as the basis for updating its budget projections for 2020 to 2030. The agency currently plans to release those budget projections later this summer.

This economic forecast provides CBO’s first complete set of economic projections through 2030 since January and incorporates information available as of June 26.1 The baseline forecast is being published now, rather than later with the budget projections, to provide the Congress with CBO’s current assessment of the economic outlook in a rapidly evolving environment. This economic forecast updates the interim forecast that CBO published in May, which focused on 2020 and 2021.2 It is similar to the May forecast for those two years, except that the projection of growth in the second half of 2020 has been revised downward. The 2020 coronavirus pandemic has brought about widespread economic disruption. To mitigate the contagion, governments, businesses, and households in the United States and around the world have taken measures to limit in-person interactions. Collectively referred to as social distancing, those measures include reducing social activities and travel, curtailing the activity of schools and business, and working from home. In the first quarter of 2020, the pandemic and associated social distancing ended the longest economic expansion and triggered the deepest downturn in output and employment since World War II. CBO projects that if current laws governing federal taxes and spending generally remain in place, the economy will grow rapidly during the third quarter of this year.

We recently had a customer out in Winter Haven who needed their kitchen remodeled. This job was then promptly introduced to a local installer who orders their doors from one of Dackor's local press customers in Florida. The cabinetry needed to be laminated to a cream white color to match the walls. They had an island and lower cabinets that needed to be laminated in a navy blue color to match the aesthetic. Not to mention, there were many different new kitchen appliance installations that would affect the laminate application process. When all was said and done however, the results were night and day! The Perfect Touch Snow White cabinetry matched the walls of the house nicely to maintain a clean look. The Perfect Touch Mysterious color on the island and lower cabinets complimented the aesthetic of the kitchen nicely in a way that didn't take away from the granite countertops. And all of this was done seamlessly to make room for a whole new set of appliances to compliment the fresh new look. Let us know what you think ! Perfect Touch Royal Blue

$0.50

ID: S075 - View Larger Image Specs: 0.35mm x 1420mm, Super Matte Finish *Click "Add to cart" to order a sample swatch ANCHORED COATING

A coating applied to a base sheet (usually bonded) so it very strongly resists separation. ANNEALING Technique of keeping a material for a period of time at a temperature short of melting, to relieve internal stresses; the application of heat to a formed or oriented plastic article to relieve stress resulting from the forming or orientation process. ANTI-BLOCK The name for a treatment applied to plastic film surfaces to keep them from sticking together or “blocking” when they are tightly rolled up on a mandrel. ANTIOXIDANT A substance that prevents or reduces oxidation of the material by air or oxygen. ASEPTIC Free from septic matter or disease-producing bacteria. In food processing and packaging, this is an adjective that describes the system used to package food in a sterile fashion. BBAG, CRIMP-BOTTOM A flat bag with a crimp-seal bottom (no fold-over), usually heat-sealed using serrated dies. Not a particularly strong type of bag (see: Flat Bag). BAG, DUPLEX A bag constructed of two plies of material, generally spot-sealed to each other, especially at the mouth. BAG, FLAT Simplest form. A web of material folded into a flat tube with side or center seam, then cut off and sealed at one end. Has only two dimensions: length and flat width. Flat bags may have a crimped seal or a fold-over seal, in which a short section is turned back and sealed in place by heat, adhesives or a combination of both. BAG, GUSSETED Bag having bellows-like folds on each side that expand outward when bag is filled. BAND In cellophane, a dark-colored circumferential ring in a slit roll, caused by a slightly heavier moisture content, or very slight variations in base-sheet thickness. BANDS, BAGGY A defect in a roll of film; a slack lane or a baggy section which shows up when film is unwound and pulled taut. BEAD A thickened section at the edge of a roll of film. In cellophane slit rolls usually caused by moisture absorption into the cellulose base sheet. BETA-RAY GAUGE Consists of two facing elements, one emitting and one detecting beta radiation. The device accurately measures density or thickness when mounted above and below the web. BIAXIAL ORIENTATION A process for orienting a plastic film in both the transverse and the machine directions. BLEEDING Diffusion, especially of inks, into areas adjacent to those that were intended to be printed. BLISTER PACK Package formed from semi-rigid thermoplastic material so that the sheet forms a transparent dome over the package item. BLOCK, BLOCKING Undesired adhesion of two or more plies of material in roll or sheet form. May be caused in cellophane by exposure to excessive heat, pressure or humidity; in printed film, occasionally caused by improper or insufficient drying of inks, resulting in printed areas sticking together. BLUSH, BLUSHING Hazy or foggy appearance occasionally noted in coated films. BON Biaxially Oriented Nylon. BREATHING Passage of gases into or out of a package. Certain films are designed to permit it. CCELLOPHANE Transparent film made from regenerated cellulose, a fibrous material occurring in plants. CELLULOSE, REGENERATED Cellulose that has been chemically treated, then regenerated as a transparent film. CEMENT In the adhesive sense, a substance bonding two materials by chemical or solvent action. CHEEK-PLATES Discs used at each end of paper or rolls of film to prevent “telescoping” of material. CLARITY Freedom from haze; transparency. CLING Adhesion of packaging films to machine surfaces: “drag.” Often caused by tackiness or static electricity charges in plastic films. COATING, FILM A coating applied to provide protective, decorative, pressure-sensitive, waterproof or heat-sealable qualities to the base sheet. COATING, HEAT-SEAL A coating, applied to a base sheet, which may be activated by heat to permit the fusion or seal of one section of the film to another. COEXTRUSION Simultaneous extrusion of more than one polymer layer into a film. COF Coefficient of Friction. COHESION The tendency of a mass to hold together by primary or secondary valence forces (intermolecular attraction). COLOR-OFF In cellophane, slit roll edge may display variation in color or shade; off-color film is not usually defective, will almost always perform on machines. CONTOUR PACKAGE Package formed of semi-rigid material, usually by shaping a heated sheet by pressure or vacuum so that it follows the contours of the packaged item very closely. CONVERTER, PACKAGING Equipment which processes raw packaging stock such as cellophane, foil, etc. into a more advanced state, generally by forming, printing, gluing, laminating, etc. CORE SIZE Inside diameter of the core. CORONA TREATMENT Subjecting a polymer film to an electrical discharge to alter its surface characteristics. CRATERING Thin or bare spots in a film that appear as pockmarks. CRAZING Network of fine lines in or on a coating or transparent surface: “spider web” or “dried mud” pattern. CRIMP SEAL Seal produced in cellophane or other material by means of elements having corrugated surfaces; lends mechanical rigidity to seal areas as well as ensuring maximum area contact of film surfaces. CROCKING Smudging or rubbing-off of ink after printing. CURL In packaging films, distortion frequently caused by the absorption, or loss, of moisture at an uneven rate from one side of a sheet; curl may also be caused by uneven physical stresses, as in the case of laminations or coated materials. CUT-OFF LENGTH Length of sheet fed by automatic wrapping machine during operation. CYCLE TEST Test program in which items are exposed alternately to two or more test conditions. DDEAD-FOLD Fold in packaging material which will remain in place without sealing, as in the case of folds made in soft lead foil or aluminum foil. DIMENSIONAL STABILITY The absence of dimensional change of a material when subjected to changes in temperature, humidity, heat or aging. DOCTOR-BLADE Scrapers that regulate the thickness of adhesives, or inks, on a feed roller. DOWNGAUGE Use a thinner film than had been previously used. DRAW-DOWN Thinning in gauge or narrowing in width, especially of extruded materials, as a result of windup rate exceeding speed of extrusion, stretching. DYNE A measurement unit of force (centimeter-gram-second) traditionally used to quantify the energy on the surface of a film as an indicator of its ability to accept inks or coatings. EELECTRONIC SEALING Sealing of surfaces in contact with one another by high frequency current, e.g., sealing vinyl sheet. Heat is generated within the film by high-frequency agitation of the sheet’s molecular structure. EMULSION A non-separating dispersion or suspension of a solid in a liquid. EXTRUSION LAMINATION A process for joining two webs by feeding them through a machine that extrudes a thin layer of plastic between them to act as an adhesive. FFILM, CALENDERED A film manufactured by forcing base material through rolls of a calendering machine, making it smooth and glossy. FILM, CAST (1) Film made by pouring or metering material onto a highly polished moving drum or endless belt, or (2) film produced by extruding into a solution, as in the case of cellophane. FILM DENSITY The ratio of the weight of a body to the weight of an equal volume of water at some specified temperature (same as SPECIFIC GRAVITY). FILM, EXTRUDED Film produced by the extrusion method. FILM, NON-FOGGING Film that does not become cloudy from condensation of moisture caused by temperature drops or humidity changes. FILM, ORIENTED Film in which the molecular structure is aligned mechanically in one or more directions, thus giving the film more strength while introducing shrinkage characteristics. FIN SEAL Seal that results when edges of two superimposed sheets are bonded, resulting in a pouch having fin-like protuberances. FISH-EYES Particles of undissolved extraneous material in a film or coating. FLAT SEAL A method of heat sealing thermoplastic films with a flat bar surface. FLEX CRACK Cracking in a film produced by repeated flexing. FLEX STRENGTH The ability of a sheet or film to withstand breakage by folding. Measured by a test to determine the number of folds required to cause failure. FRACTIONAL PACKAGING Interior packaging of individually wrapped units so that unused portions will be protected after outside package has been opened. Usually used for biscuits, crackers and ready-to-eat cereals. FUSE Weld of thermoplastic materials by heating to point just above that at which they soften. GGAS PACKAGING Packaging in a gas-tight container in which air has been replaced by a gas such as carbon dioxide or nitrogen. GAS TRANSMISSION The movement of gas, air, oxygen, etc., through a film material. The gas transmission property (permeability) of a film is measured in terms of the volume of gas (at standard temperature and pressure) transmitted through a given area of film of a given thickness, within a given time. GASSING (1) Development of gas in a sealed package. (2) Removing air from a filled package and replacing it with another gas such as carbon dioxide or nitrogen. GAUGE Thickness expressed in decimals of an inch or in millimeters. GEL A general term used to describe a defect consisting of insoluble polymer causing a visible discontinuity in a film. GHOSTING Reproduction, very faint, of printed design without actual ink transfer. GLASSINE Smooth, dense-structured super-calendered paper, translucent or opaque, made from heavily beaten fibrillated chemical wood pulp. Grease-resistant, tough, pliable. GLASSINE, COATED The coating types available include hot-melt-applied paraffin waxes and derivatives, as well as solvent-applied types made from cellulose nitrate, vinyl polymers and other synthetic or natural rubber polymers. GLASSINE, LAMINATED Glassine laminated to itself, or other paper, films and foils, to obtain added strength and made-to-order protective water-vapor properties. HHDPE Abbreviation for high density polyethylene. HEAT SEALING A method of bonding two or more surfaces by fusing thermoplastic or thermosetting coatings of films under controlled conditions of temperature, pressure and time (dwell). HERMETIC SEAL A seal that will exclude air and be leak-proof. HOT-STAMPING MACHINE Marking machine that applies a code mark or date on a package or a wrapper with a heated stamp. HOT TACK The property of an adhesive or seal layer to resist forces that would pull the seal apart while it is still hot. HUMIDITY Water vapor in air. Absolute humidity is the weight of water vapor contained in a unit of air. Relative humidity = percentage of actual humidity to the maximum humidity which air can retain without precipitation at a given temperature and pressure. HYGROMETER An instrument for measuring the moisture of relative humidity in the atmosphere. HYGROSCOPIC Having the property of absorbing moisture readily from the atmosphere. IID Inside Diameter. IMPACT STRENGTH Resistance of a material or product to shock, such as from dropping and hard blows. IMPREGNATION Saturation of a material with another substance. INK, GRAVURE Pigment dissolved or dispersed in a vehicle made from resins and solvents; very fast drying. INK, IMPRINTING Ink specially designed to be used with a marking device. INK, MOISTURE-SET Ink formulated to be stable under normal humidity conditions, but to set up or harden when exposed to very high humidity. INK, THERMOSETTING Ink formulated to be stable and free from tack at ordinary temperature but to set up quickly at elevated temperatures. IRREGULAR WINDING (Projecting film) Peaks or ridges in a slit roll that extend out more than 1/32” from edge of main body of roll. IRREGULAR WINDING (Lateral weave) A defect whereby a difficulty shows up as failure of film to feed in straight line during use. LLABEL, HEAT SEAL A label coated on one side with a heat-seal coating; usually a thermoplastic resin. LAMINATE (noun) A structure made by bonding together two or more layers of material or materials. (verb) Action of combining finished films to produce the laminate. LAMINATED FILM Combination of two or more films or sheets made to improve overall characteristics. LAP SEAL Any seal made between two overlapping films. Used in contrast to a “fin seal”. LDPE Abbreviation for low density polyethylene. LIP That part of the tube of a flat or square bag, or pouch, extending beyond the face of the bag. LITHOGRAPHY, OFFSET: Printing process using etched metal plates. Ink adheres to etched area, is transferred to rubber printing blanket, from there to paper to be printed. LLDPE Abbreviation for linear low density polyethylene. MMAKE-READY In printing, preparation of press for a run; especially, making all printing surfaces uniform in height. MASTER ROLL The large roll of film wound during a film formation process, which is normally slit into smaller rolls for later processing or shipment. MD Abbreviation for machine direction. METALLIZING The process of applying an extremely thin metal coating to a non-metallic substrate. MIL One thousandth of an inch. MODULUS In packaging, used to denote the degree to which a film or sheet resists stretching before it reaches its elastic limit when an external force or stress is applied. MSI Abbreviation for a thousand square inches, a common unit for pricing laminated films. MVTR Abbreviation for moisture vapor transmission rate. NNITROCELLULOSE Any ester of nitric acid and cellulose. NICKED EDGES Edges of film split or torn. NON-FLAMMABLE or NON-INFLAMMABLE Will not support combustion. OOD Outside diameter. OFFSET Accidental transfer of printing inks or coating from surface of a sheet to back of another sheet. OPACITY Resistance of material to transmission of light. OPP Oriented Polypropylene. OPTICAL DENSITY A measure of opacity of a metallized film layer. It is the log of the ratio of the intensity of transmitted light to incident light. OPTICAL DISTORTION Change in appearance of object when viewed through a transparent material having certain defects, such as waviness of surface, etc. OVERPRINT The result of printing one layer over another, such as one layer of ink printed over another one to form color combinations. OXIDATION Reaction of any substance with oxygen. PPACKAGING, FLEXIBLE Packaging involving the use of such flexible material as foils, films, paper, etc. to form the container. PACKAGING, FRACTIONAL The breaking down of a unit package into two or more sub-units, with the objective of protection of the sub-units. PAPER, SULFATE Kraft paper, a chemical wood pulp paper (the strongest pulp paper made from wood). PAPER, SULFITE Any type of paper made from pulp produced by the sulfite chemical process. Used in packaging applications where appearance and printability are of primary importance. PAPER, WAX or WAXED All papers that have been impregnated, coated or otherwise treated with waxes or waxlike materials. PAPERBOARD A heavyweight thick sheet of paper, usually a thickness of 0.06” or over. PARCHMENT, ARTIFICIAL Certain greaseproof papers made by wholly physical means, but having no natural wet strength; resembles vegetable parchment. PARCHMENT, VEGETABLE A vegetable-base paper having no taste or odor, consisting only of pure cellulose. Highly greaseproof, and outstanding in wet strength. PE Abbreviation for polyethylene. Used when someone wants to avoid being specific, but is usually synonymous with low density polyethylene. PEEL-SEAL A package seal made using an adhesive that can readily be peeled open. PEELING BOND A type of bond that occurs when two adhered surfaces may be pulled apart without tearing the fibers. PERMEABILITY Ability to be permeated by gases or liquids; a measure of the freedom with which gases or liquids can diffuse through a material. PET Polyester film. pH Numerical representation of acidity or alkalinity. Neutral is pH 7, pH 1 is extremely acidic and pH 14 extremely alkaline. P1 TEST PROCEDURES A large body of standard test methods developed or recommended by Technical Committees of Packaging Institute to provide uniform and reliable tests. PICK-UP ROLL A spreading device where the revolving roll for picking up the adhesive runs in a reservoir of liquid adhesive. PLASTICIZER An agent or compound that is added to plastic materials to impart softness or flexibility. PLASTICIZER MIGRATION Movement of plasticizer to the surface of a plastic, or from one plastic to another, or from a plasticized substance into the atmosphere; causes embrittlement. PLATE (noun) Curved or cylindrical shape carrying printing impression, for use on a printing press. POLYMER A compound formed by the linking of simple and identical molecules having functional groups that permit their combination to proceed to higher molecular weights under suitable conditions. POLYPROPYLENE A synthetic thermoplastic material of high molecular weight resulting from polymerization of propylene gas under pressure and heat, plus catalysts. POLYSTYRENE A thermoplastic material derived from the polymerization of styrene monomers. POROSITY Of sufficiently loose texture to permit passage of liquid or gases through pores. POUCH, PLICATED A folded pouch having gussets. PPR Polypropylene. PRESS POLISH A finish for plastic sheet stock, produced by contact under heat and pressure with a very smooth metal, which gives the plastic very high sheen. PRIMER, PRIMED The act of putting a thin coating on a substrate so that it will be more receptive to printing inks or adhesives. PRINTING COMPENSATOR A mark printed at regular intervals on the film which actuates a photoelectric cell on the bag machine or wrapping machine to insure the perfect register of copy on a bag or package. PRINTING, FLEXOGRAPHIC Formerly called aniline printing. A method of rotary letterpress printing that employs flexible rubber plates and rapid-drying inks. PRINTING, GRAVURE A rotary printing process employing minute engraved “wells” in an etched metal cylinder. Deeply etched wells carry more ink than shallower ones, hence print darker values. A doctor blade wipes excess ink from the printing cylinder. Stock is web-fed from roll. PSYCHROMETER A hygrometer for measuring water vapor in the atmosphere. PULLOUT, GOOD No puckers or banded lanes showing when film is stretched. RREGENERATED CELLULOSE A cellulose hydrate. The term is used to designate films made from a cellulose base. REVERSE PRINTED The process in which a transparent film is printed backwards so that when it is flipped over, the printing appears right side up. When used in a package, reverse printed film will always have the printing ink on the inside where it is protected from scuffing and abrasion. REWIND To wind again; especially the winding of a roll of film after printing, slitting, etc. RH Relative humidity. ROLL FORMATION A general term denoting qualitatively how evenly, smoothly, and regularly film is wound on a roll. SSERRATED Saw-toothed. Describes the configuration used on heat-sealing equipment for obtaining a crimp seal. SLIP A measure of coefficient of friction (COF). High slip means low COF. SLIT To cut a roll of stock to narrower widths. SLITTER A machine to cut a roll of stock in the long direction. SOLVENT SEALING A method of adhering packaging materials which uses small amounts of volatile liquids to soften the coating of the material so it will bond. Examples: cellosolve ethyl lactate, etc. SPECIFIC GRAVITY The ratio of the weight of a body to the weight of an equal volume of water at some specified temperature (same as FILM DENSITY). SPLICE: To unite or join the ends of roll materials by mechanical or electrical means, or by an adhesive. STATIC ELECTRICITY Charges of electricity sometimes generated during handling or in machine operations; may cause undesired attraction of film to roller, flat surfaces, etc. STERILE SEAL A closure for bacteria-free medical supplies that must maintain sterility. STERILIZABLE The ability to withstand contact with steam (moist heat) at 30 lb. pressure for 30 minutes, or contact with dry heat (circulating hot air) at 200°C for 15 minutes. STRIP-PACKAGING Small articles packaged individually or in multiples in continuous strips, divided in segments or pockets that permit easy tearing off or cutting off. SUBSTRATE A film to which subsequent layers or coatings are added. SURFACE PRINTING Printing on the outside surface of a package as opposed to one of the inside surfaces (see “reverse printing”). SURFACE WINDING A method of winding film on rolls in which the winding force is provided by the driven roll in contact with the surface of the winding roll. SURLYN Dupont’s trademark for its line of ionomer resins. Films produced with this resin have excellent seal characteristics such as lower sealing temperatures and excellent hot tack. TTAPE, CELLULOSE ACETATE A translucent, pressure-sensitive adhesive tape of cellulose acetate laminated to strong tissue. TD Abbreviation for transverse direction — the direction perpendicular to the machine direction. TEAR STRENGTH The force required to propagate a tear already initiated by a cut on the edge. TEAR STRIP A narrow ribbon of film, usually incorporated in the wrapper or overwrap during the wrapping operation, to facilitate opening of the package. TELESCOPING Side-slipping of layers of a coiled material so that the edges no longer form a plane surface. TENSILE STRENGTH Resistance of a material to longitudinal tension. TEST, CELLOPHANE TAPE A simple test for determining the permanency of printing on plastic film. A length of pressure sensitive cellophane tape is pressed on a section of printing and then pulled off in one motion to see whether or not the ink lifts with it. The angle and speed of the pulls are important. TEST, DROP A package durability test. Filled containers are dropped from controlled heights. A special device insures uniformity of drops. TEST, DRUM Rough-handling test for filled container, inside a revolving hexagonal drum. TEST, ELMENDORF TEAR A method of testing film for resistance to tearing. The weight required to tear one of several layers of notched film is measured. TEST, FOLDING ENDURANCE A test to evaluate the endurance of films to folding, frequently done on a Schopper machine. TEST, MULLEN The Mullen is widely used on film packaging materials to determine the relative bursting strength. THERMOCOUPLE A bimetallic device to measure temperature electrically. THERMOPLASTIC Capable of being repeatedly softened by heat and hardened by cooling. THERMOSTAT An automatic device for regulating temperature; uses bimetallic strip to make and break contacts of electrical circuit. THERMOSET Plastic that is heat set. THERMOWELD To weld together two or more surfaces of a thermoplastic film material by means of heat. TIE LAYER The common term for a coextrudable adhesive. TRACKING A film that follows a desired path on a packaging machine without constant adjustment is said to “track” well. TRANSLUCENT Permitting passage of light, but diffusing it to such a degree that objects cannot be seen clearly; something short of transparent. TRANSPARENT Transmitting rays of light so that objects can be clearly seen through the material. UUNDERFOLD To fold wrapping material in such a manner that the end folds are turned under the bottom of the package, then sealed to the underside. VVAPOR TRANSMISSION The passage of vapor (usually water vapor) through a material. VFFS Abbreviation for vertical form-fill-seal. VISCOSE A viscous orange-colored liquid obtained by treating cellulose with caustic alkali solution, then with carbon disulfide. VISCOSITY That property of a liquid material that tends to resist flow. VOLATILE Passing from a liquid into a gaseous state. VOLATILITY The rate of evaporation of a solvent. WWATER VAPOR PERMEABILITY The ability of a material to permit transmission of water vapor. WATER VAPOR TRANSMISSION RATE Measure of permeability of a material, often stated in terms of grams of water passing through 100 square inches of material in 24 hours at 100°F and 90 percent relative humidity. WAX, MICROCRYSTALLINE A petroleum wax of high molecular weight, characterized by minute crystals and distinguished by its solid wax-like appearance at room temperature. WEB A term to denote a long film somewhere in the processing stage, frequently being drawn off a large roll. For example, a “printed web” would be a large roll of printed film. WORMING Channel-like delamination pattern in adhesive-laminated materials. WRAP, BUNCH Wrapping with packaging material gathered on the underside of package in somewhat irregular manner. WVTR Abbreviation for water vapor transmission rate. YYIELD Area per unit of weight, usually expressed as square inches per pound. There are two popular ways to tell if a thermofoil component is manufactured well. The first is the appearance and the second is the adhesion on the edges. Appearance examples: - Telegraphing of the mdf through the film - visible wrinkles, shadowing, defects - overstretched corners or whitened corners Adhesion: - clear bite of the film to the edge of the component. You can tell by a pull test - adhesion down in raised panel profiles, no bridging For the sake of this post, I'd like to discuss why and when to do a pull test. Firstly when the heat is activated well the film will stick well to the sides of the components. Examples are below: Good times to do a fiber pull test are: - When lowering temps significantly - When changing film thicknesses more than .1mm - When adding working with a new vendor - When adding a protective film In conclusion, pull tests are great way for manufacturers to spot check their components to better ensure good adhesion on the sides of the components and can be an integral part of QC. |

Design Life blogColor inspiration from around the world, backstories on design inspiration and informative articles about marketing, membrane pressing and personal development. Author Mark Viers delivers fresh content that will help you and your business grow and thrive. Categories

All

Popular articles Language of Color Breaking membranes? Delamination Tearing on corners Solving wrinkles Solving dog ears Video installing peelstix 3DL for high end kitchens Pompeii design inspiration Archives

May 2024

|

RSS Feed

RSS Feed